- Customized Stainless Steel/Carbon Steel/steel Lost Wax Casting/Investment Casting/precision casting impeller/steel part

- Material:

Stainless Steel: JIS SCS1, SCS2, SCS13, SCS13L, SCS14, SCS14L/ DIN G-X7Cr13, G-X20Cr14, G-X6CrNi18 9, G-X6CrNiMo18 10, 1.3955, 1.4308, 1.4408, 1.4581 / ASTM/AISI CA-15, CA-40, CF-3/304L, CF-3M/316L, CF-8/304, CF-8M/316, etc Carbon Steel: JIS SC450, SCC5 / DIN GS-45, GS-60 / ASTM WCB, 450-240, 80-40, etc Alloy Steel: JIS SCW480, SCSiMn2, SCCrMn3 / DIN GS-20Mn5, GS-37MnSi5, GS-34CrMo4, etc Heat Resistance Steel: JIS SCH13, SCH21, SCH24/ DIN G-X15CrNiSi25 20 1.4840,G-X45CrNiSi35 25 1.4857 / ASTM HN, HK30, HK, HK40, HHM HP, HT Bronze or Copper: JIS BC6, ALBC6, etc Other materials Carbon Steel, Alloy Steel, Hight Manganese Steel, Tool steel, Heat-resistant Steel, Al-Si Alloy, etc also available according to customer's request.

- Required documents for offer to be provided by customer:

Drawings with formats of IGS (3D), DWG or DXF (Auto CAD 2D), PDF, JPG

Standard of material (Preferable to provide Element Percentage of C, Si, Mn, P, S, etc and Physical/Machanical Properties of the material)

Technical requirements

Unit Weight of Rough Casting

Production technology: Lost-wax casting/investment casting

- Main production equipment:

Vertical wax-injectors

Sand glueing tanks

Wax-evaporator

Intermediate frequency electrical induction furnaces

Spectrum analyzer

Shot blast machines

Heat treatment furnaces

Heat treatment water tank

Acid solution and water cleaning tank

Buffing / polishing machines / Electrical polishing

- Unit weight: 1.2g~80,000g per piece

- Other details:

Taper hole, deep hole, bent hole D>Ø2mm L=1D

Minimum outside radius R0.3mm, minimum inside radius R0.5mm

Minimum thickness of 1.5mm, some parts with minimum thickness of 0.8mm

- Tolerance of dimension for cast:

Dimension Range (mm) Common Tolerance Special Tolerance < 25 +/- 0.25 mm +/- 0.13 mm 25 ~ 50 +/- 0.40 mm +/- 0.25 mm 50 ~ 100 +/- 0.80 mm +/- 0.50 mm > 100 +/- 1 % +/- 0.5 % - Minimum order: No limit

- Delivery: Within 30 working days after signing of contract and confirmation of samples by client

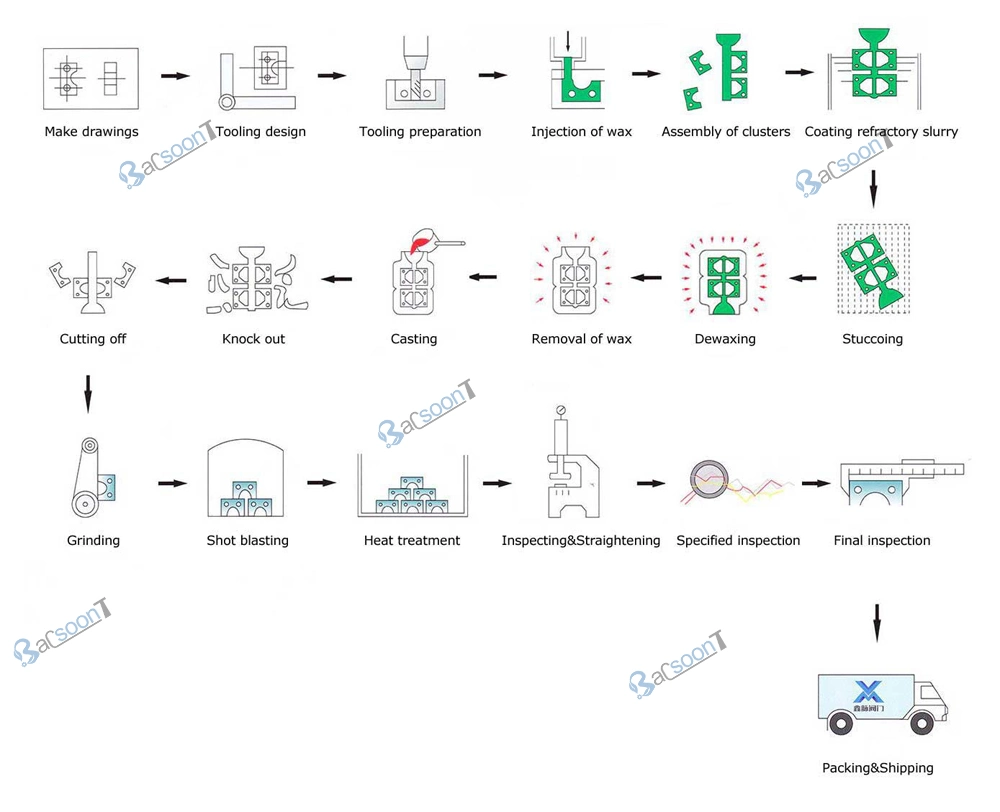

- Technological process:

- Workshop:

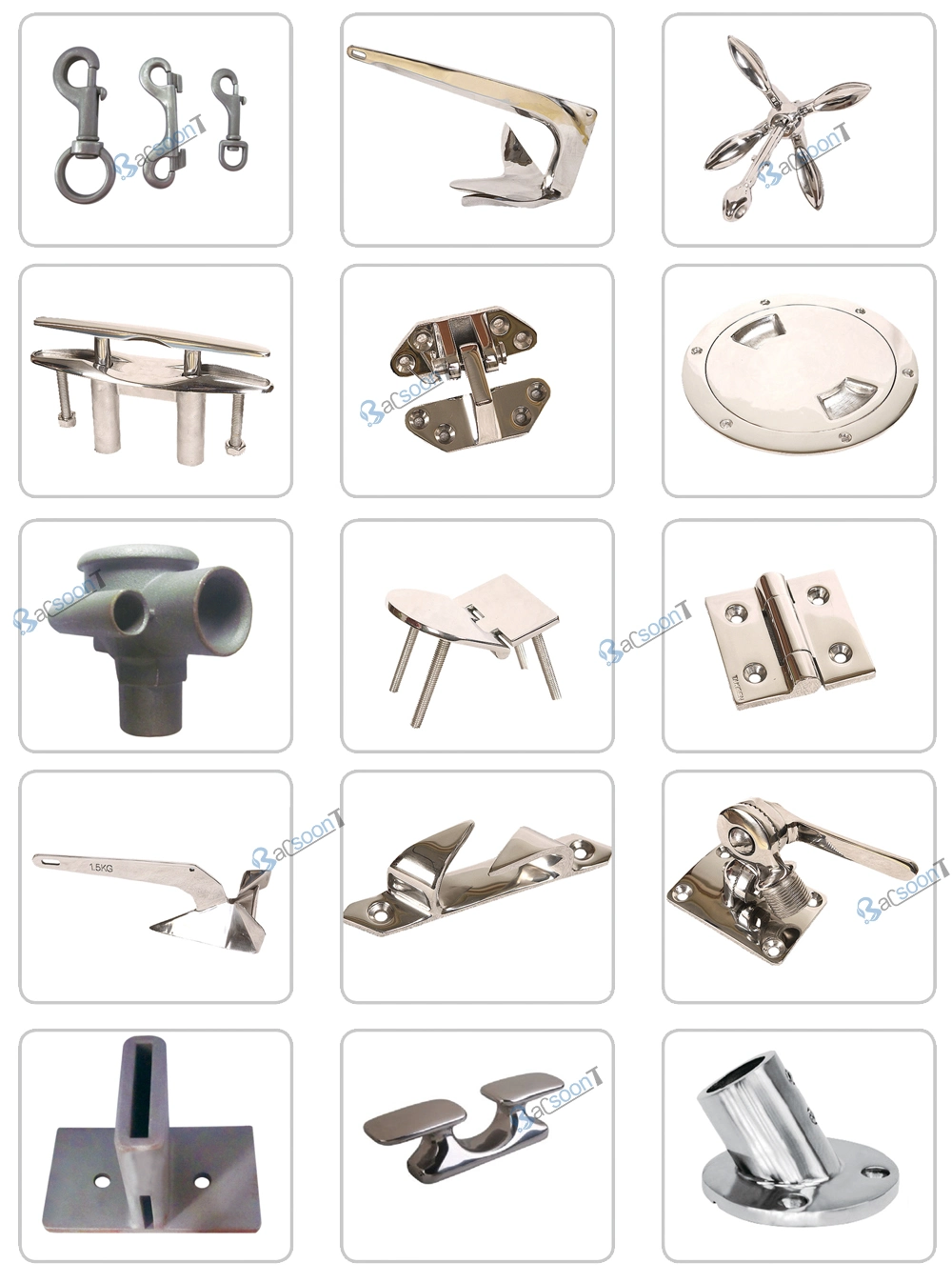

- Some Products:

- Testing equipments:

- Shipments:

- Company information:

- Certifications: